|

In addition to our complete snack and noodle production lines, we also offer a variety of special single units for specific purposes, including general-purpose oil heaters, laboratory units, and pilot production units. These units are designed to help our clients determine whether to introduce a new product on a larger scale. At Seoju Engineering, we understand the importance of innovation and flexibility, and we are committed to providing our clients with the tools they need to develop and produce high-quality snacks and noodles. Whether you need to test a new recipe or refine an existing one, we have the equipment you need to succeed.

|

Oil heater Oil heater

|

|

Compact sized new arrival frying-oil heater which is characterized by improved oil turnover rates with only half of total oil volume other heaters would contain minimizes oil degradation while providing user-friendly maintenance so as to efficiently reduce production cost and accomplishing better flavour and texture as well.

|

|

|

|

Sludge fryer Sludge fryer

|

|

To dry sewage sludge by fry-drying process obtaining high energy combustible product as a result. While condensing oily-vapour to inflammable oil, gas burns up inside the fryer eliminating foul smell. It is characterized by its outstanding performance regardless of fuel oil types.

|

|

|

|

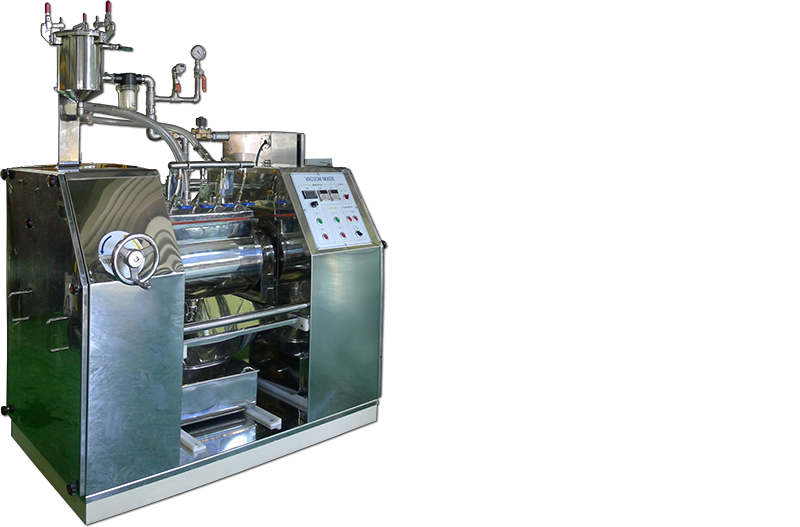

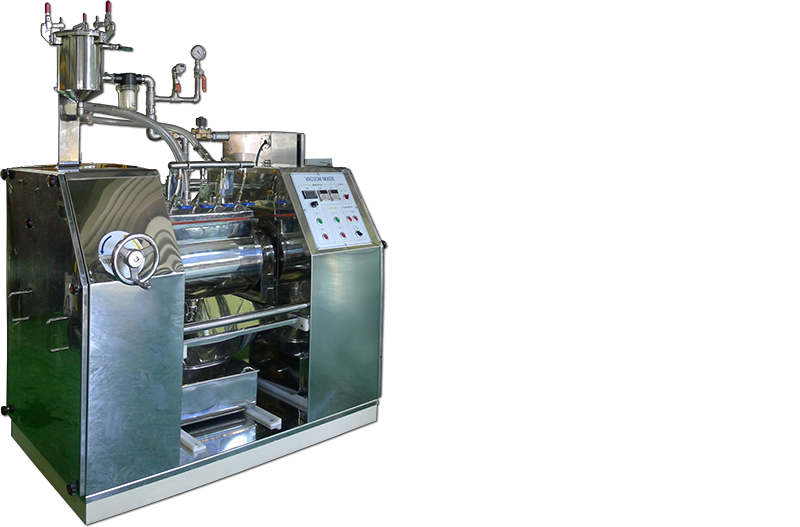

Vacuum mixer Vacuum mixer

|

|

When vacuum is applied to, it removes oxygen and therefore prevents decomposition of sensitive ingredients or undesirable chemical reactions and microbial growth. Products made by this vacuum process are relatively with minimum oxygen content to maintain high quality throughout shelf life, plus increased colour uniformity and stability with consistency.

|

|

|

|

Vacuum fryer Vacuum fryer

|

|

With our vacuum fryer it is easier to maintain natural colours and flavours of the finished product. Due to the lower temperature requirement for its frying process, the formation of suspected carcinogen acrylamide under vacuum condition is significantly lower than formation of acrylamide in standard atmospheric fryers. The fat absorption of the products is also reported to be lower than that of atmospheric fryers.

|

|

|

|

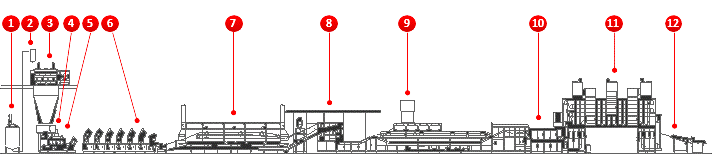

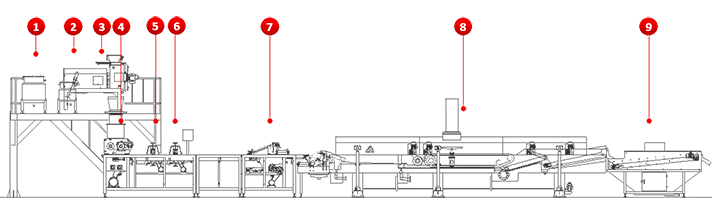

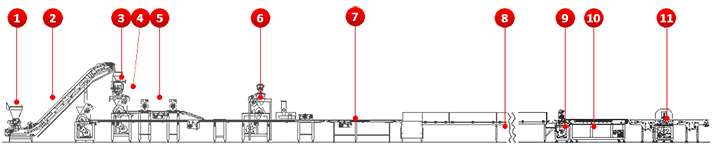

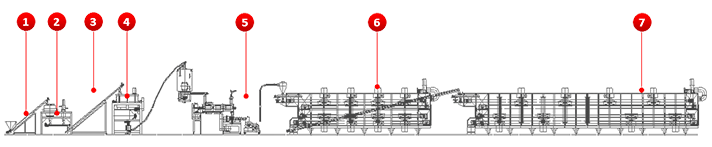

Bag type noodles

Bag type noodles

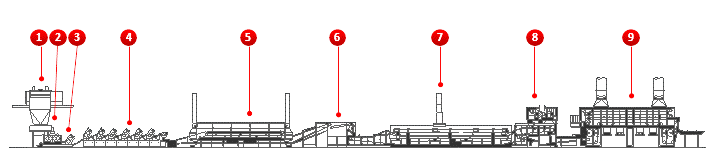

Cup/Bowl type noodles

Cup/Bowl type noodles

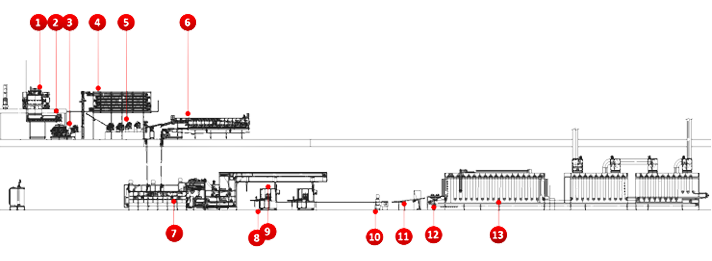

Japanese style fresh boiled noodles

Japanese style fresh boiled noodles

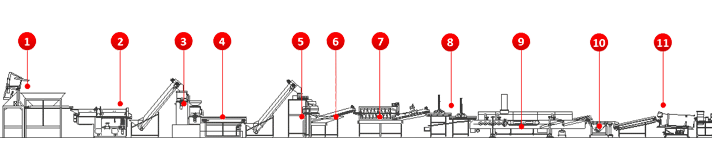

Natural potato chips

Natural potato chips

Fabricated potato chips

Fabricated potato chips

Cereal bars

Cereal bars

Frying / Roasting

Frying / Roasting

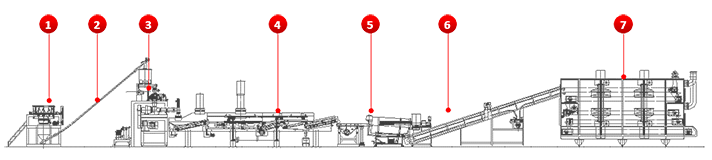

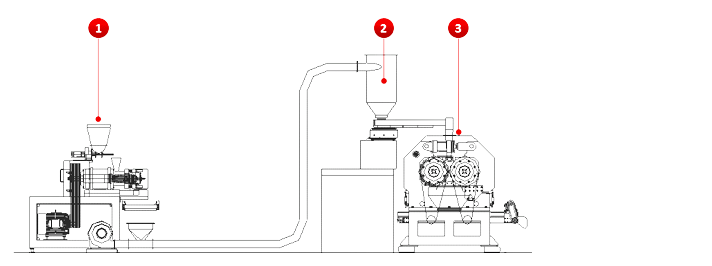

Pellet extrusion and drying

Pellet extrusion and drying

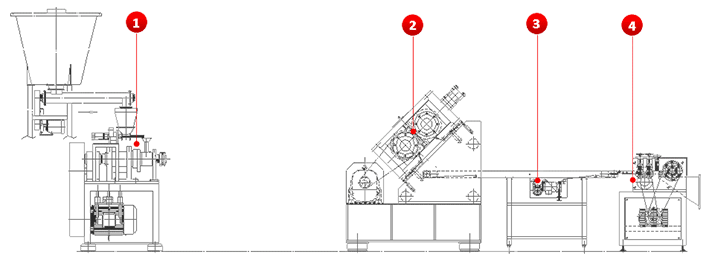

Cold extrusion

Cold extrusion

Cereal Flaking

Cereal Flaking

Corn chip

Corn chip

Oil heater

Oil heater

Sludge fryer

Sludge fryer

Vacuum mixer

Vacuum mixer

Vacuum fryer

Vacuum fryer