Snack production system

| Fully automated snack food processing machinery designed to produce wide range of snacks complying consumer's tastes. Providing highly efficient productivity, low oil usage characterizes our equipment. Flexible capacity and process designs are available upon specific requirement. | |||

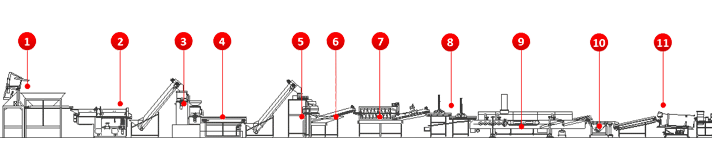

Natural potato chips Natural potato chips

|

|||

|

|||

|

|||

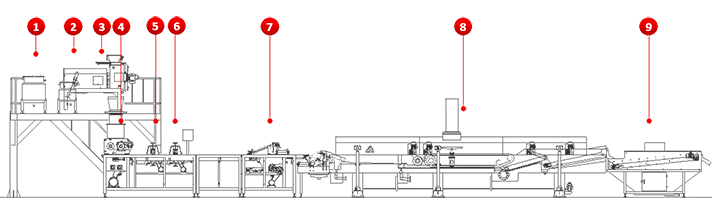

Fabricated potato chips Fabricated potato chips

|

|||

|

|||

|

|||

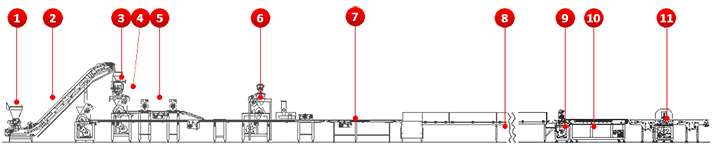

Cereal bars Cereal bars

|

|||

|

|||

|

|||

Frying / Roasting Frying / Roasting

|

|||

|

|||

|

|||

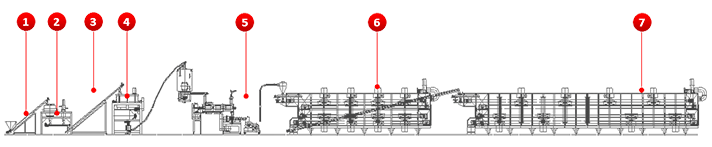

Pellet extrusion and drying Pellet extrusion and drying

|

|||

|

|||

|

|||

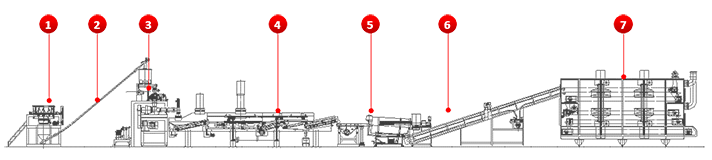

Cold extrusion Cold extrusion

|

|||

|

|||

|

|||

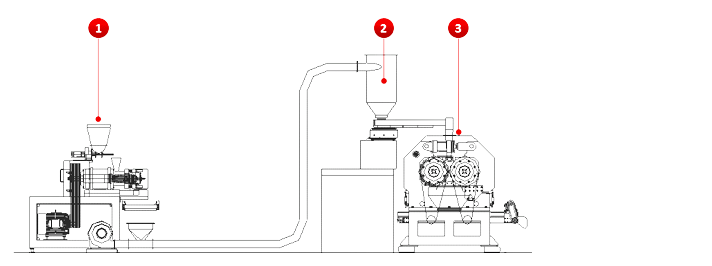

Cereal Flaking Cereal Flaking

|

|||

|

|||

|

|||

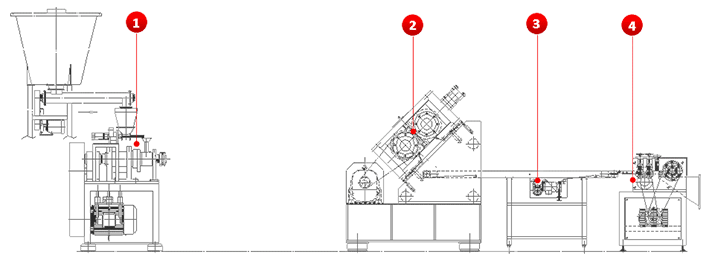

Corn chip Corn chip

|

|||

|

|||

|

|||

Other snack production systems Other snack production systems

|

|||

|

Contact us for more information |

home |

About us |

Product & Solution |

Career |

Site map |

Contact us |

Company Location |

Privacy Policy

271-27, Seoicheon-ro, Majang-myeon, Icheon-si, Gyeonggi-do, Korea (zipcode 17385)

© Seoju Engineering Co., Quality Food Processing Machinery Since 1992

271-27, Seoicheon-ro, Majang-myeon, Icheon-si, Gyeonggi-do, Korea (zipcode 17385)

© Seoju Engineering Co., Quality Food Processing Machinery Since 1992